REMOTE AUTOMATED AERATION: THE BENEFITS OF CONTROLLED AERATION IN AQUACULTURE

Fish farming suffers from a number of environmental factors that affect productivity and mortality rates . On the West Coast of the Americas , between British Columbia down to Chile, Harmful Algal Blooms (HAB) and Plankton is a large cause of fish stock mortality on an annual basis . In the Atlantic, from

Newfoundland to Scotland, Iceland and

Norway , extreme ocean temperatures exist

(high in the summer and low in the winter) causing fish stocks to dive deeper resulting in lower dissolved oxygen (DO) levels causing mass mortalities . Internationally, fish farming suffers from sea lice issues where skirts and tarps are dropped around the pens, which causes stagnant water inside the pens and a corresponding decrease in DO. Furthermore, the increased frequency of in-situ net cleaning is driving more debris into fish gills, that can be a contributor to gill health disease and poor environmental conditions. Controlled Aeration can be a tool to mitigate a number of these issues , and Remote Automated Aeration can be a cost-effective measure to optimize the life support operations for the fish farming industry.

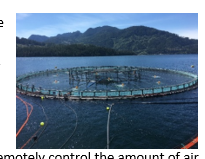

Aeration systems are an important defensive tool-in-the-toolbox for the fish farm operators to utilize in the pens in order to adjust and take control of environmental parameters such as DO, temperature, salinity, and HAB cell counts . Controlled Aeration has been effective at increasing DO levels with pens utilizing Sea Lice Skirts and HAB Tarps, allowing farms to run deeper skirts and tarps to better protect the fish stock. CPI has developed an Automated Controlled Aeration platform, called the ODiN TITAN , which allows operators and farm managers to remotely control the amount of air and oxygen being dispersed in the pens from the feed barge or at a centralized head office . When c oupled with in-pen environmental monitoring sensors, the Automated Controlled Aeration platform can adjust and react to poor in-pen environmental conditions, and then increase or decrease the air or oxygen flow in order to push out HABs and debris, up-well water from depth to mix high or low surface water temperatures, circulate stagnant pen water, and increase DO saturation levels. In addition, the ODiN TITAN can collect, store and profile historical data which is synchronized to local weather, wind, tidal and current conditions in order to develop analytical models that allow fish farming companies to optimize their operations and reduce mortalities on a cyclical annual basis. The ODiN TITAN provides a verification method to head office and insurance companies to ensure that in the case of a mortality event, that it can be proven that the operators did all they could with the Life Support tools available.