BIOECONOMIC ANALYSIS OF IN-POND RACEWAY SYSTEM GROWING STOCKER AND FOODSIZE HYBRID CATFISH PLUS TILAPIA

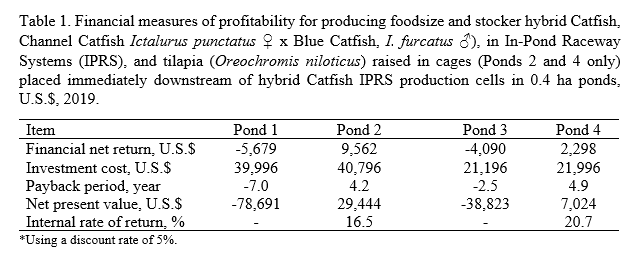

In Pond Raceway systems consist of floating or fixed floor rectangular raceways (RW) assembled or placed into existing earthen ponds. This case study evaluated the performance and economics of producing foodsize hybrid Catfish and stocker sized fingerlings (Channel Catfish Ictalurus punctatus ? x Blue Catfish, I. furcatus ?) in In-Pond Raceway Systems (IPRS) and tilapia (Oreochromis niloticus) grown in cages, placed into four 0.4 ha ponds. Growout raceways in ponds 1 and 2 were 63 m3, and 45 m3 in ponds 3 and 4. Each pond had one (14 m3) stocker unit raceway plus a 36 m3 tilapia cage placed into ponds 2 and 4. Each pond had 5.0 HP of aeration that maintained adequate DO levels. Catfish were fed a 32% CP commercial diet twice a day; tilapia were allowed only to graze the phytoplankton flow generated by the growout and stocker IPRS units. The combined production from growout (186 days) and stocker (142 days) resulted in 19,712 kg/ha in pond 1, 19,302 kg/ha in pond 2, 19,426 kg/ha in pond 3, and 16,555 kg/ha in pond 4. The same number of tilapia were stocked into the two cages and resulted in yields of 2,167 kg/ha (pond 2) and 2,160 kg/ha (pond 4); when combined with catfish production resulted in total gross production of 21,469 kg/ha in pond 2 and 18,715 kg/ha in pond 4. Foodsize average harvest weights ranged from 670 to 894 g, with survival rates ranging from 86 to 98 %, and having weight gain per day (WGD) of 1.74 to 3.22 g/day. Raceway stocker unit achieved harvest weights ranging from 173 g to 186 g, with survival rates ranging from 75 to 90% and having WGD from 1.02 to 1.37 g. In general, efficient FCRs were achieved in all growout and stocker hybrid Catfish IPRS units. Hybrid Catfish raised in IPRS demonstrated excellent fish inventory control, promoted uniform hybrid Catfish production, with 90 to 95% of the foodfish harvested in the preferred premium size range. Production strategies for inclusion of co-cultured tilapia along with the catfish IPRS systems were achieved with little investment and operating costs, resulting in overall positive net returns. Ponds housing IPRS catfish units plus a tilapia cage had reduced investment payback periods, increased net present value and higher internal rates of return (Table 1).