INNOVATIVE CONTAINMENT TECHNOLOGY-NET PEN BIOFOULING CONTROL, THE ULTRASONIC METHODOLOGY

Keeping subsea nets clean has been a challenge since the first fish farmer began operations. Cleaning can damage the aquatic environment as well as pose high costs for fish farmers. Current antifouling and net cleaning solutions may pose unnecessary risk and potential harm to fish health, general husbandry, and most importantly, the receiving environment. The focus is now on green technologies (new and proven) to reduce risk to the aquatic environment.

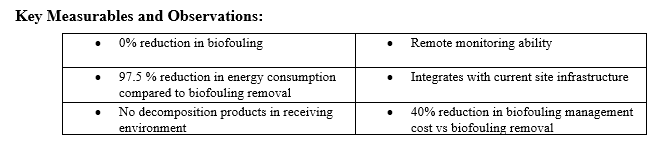

Using a first principles approach to biofouling, eliminating growth from starting on the subsea structure is the objective. Combining leading edge material science with proven ultrasonic technologies in the marine shipping/vessel industry is a new way forward for controlling growth on net pens. By transmitting ultrasonic through a specialty net fibre construction ultrasound produces a pattern of increasing and decreasing pressure on the surface of the net which causes a process called non-inertial cavitation. This causes microscopic bubbles to be created by the reduced pressure cycle implode as the pressure increases. The microscopic agitation has a cleansing effect which destroys surface algae. By disrupting this first link in the food chain, the surface is kept clean and makes it much less hospitable for larger organisms that feed on the algae.

Badinotti Combi Net combines traditional textile material blended with steel which provides additional inherent benefit of heightened Predator Protection . Raschel construction ensures 100% consistent and equal coverage of both materials and provides lower total weight and flat face as compared to heavier knotted nets. Badinotti Net provides premier conductivity as compared to knotted equivalent and has superior weight and breaking load ratio with the lowest weight fibre within the aquaculture industry. Consistent and stable high quality raw material supply chain of Dynema in all global markets indicates that cage control methods and technologies are on the verge of disrupting the market . The biggest impact is anticipated in the salmon farming market where fouled containment structures pose the greatest risks of fish health, environmental impact, cost, and social pressure.